Product Details

Tauvis Interior Paint

Lime-Based Natural Mineral Coating

1. Product Description

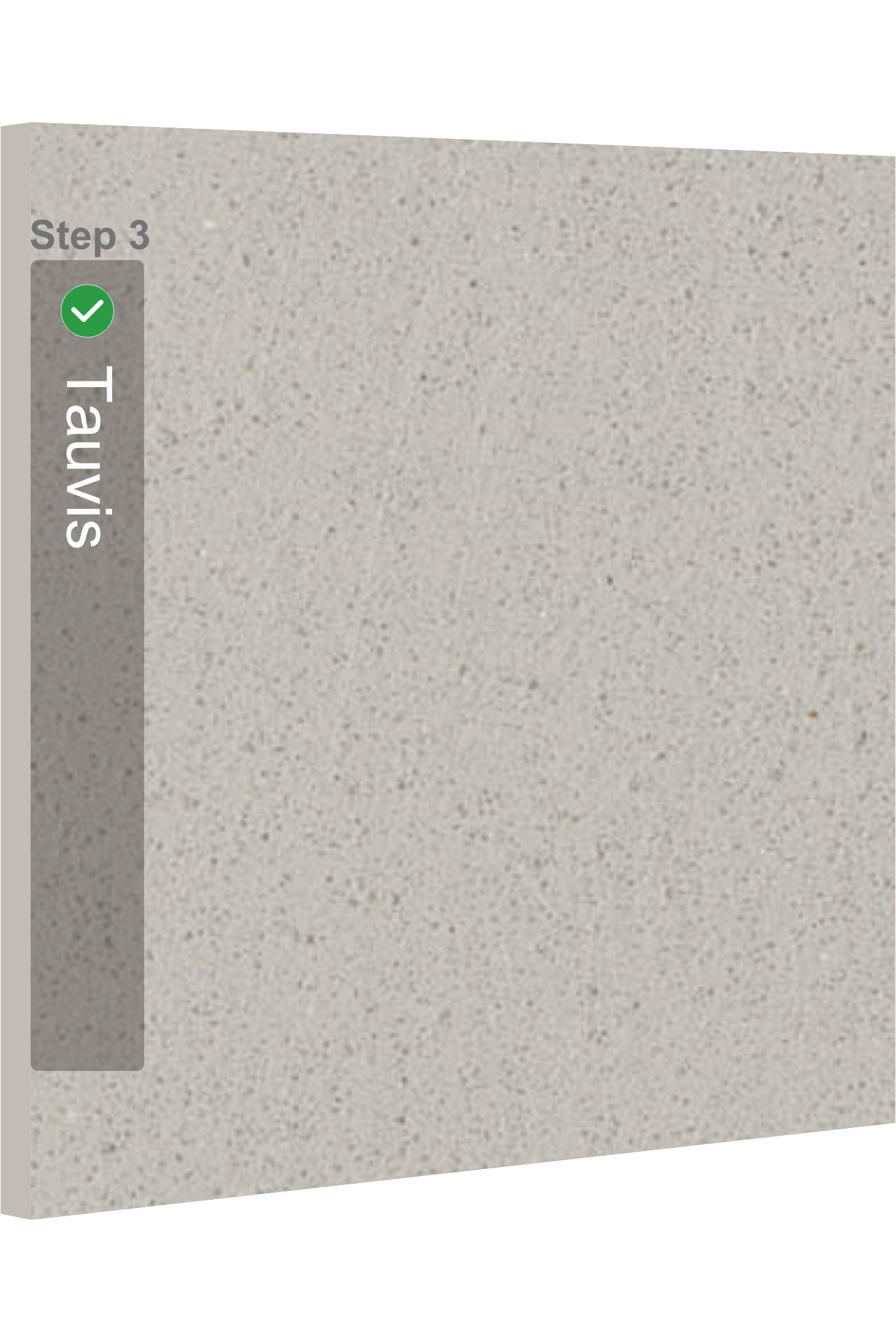

Tauvis is the latest upgraded natural lime-based mineral coating, hereinafter referred to as "lime-based coating". Its biggest highlight is that after polishing, the finished product greatly reduces the sparkling spots of crystalline sand, presenting a more natural and high-end effect. It is made of high-precision mineral raw materials through dozens of careful selection processes, pursuing excellence in every detail.

The product features natural and unique stone-like textures, which are durable and never go out of style. It has high density, high hardness, good flexibility, and will not crack even when bent at a low arc. It also offers a skin-like touch, has a certain degree of breathability, but does not absorb surface moisture. With waterproof function, it can be soaked in water without applying a topcoat or waxing.

It is available in four different specifications: Extra Coarse, Coarse, Medium, and Fine. It has strong plasticity, smooth construction, slow drying, no unevenness when applied, and a wide range of process extensions, realizing the super function of one product with multiple uses, thus reducing the cost waste caused by a large number of products. It is highly praised by high-end users at home and abroad.

Equipped with super odor-free technology, the product is in the form of white paste with no irritating odor. It has near-zero formaldehyde, near-zero VOC, and near-zero APEO, creating a fresh and natural indoor air environment.

2. Functional Features

1. Natural texture

2. Skin-like touch

3. Strong flexibility

4. Antibacterial and mildew-proof

5. No peeling when soaked in water

6. High-end matte finish

7. High hardness

8. Near-zero formaldehyde

9. Near-zero VOC

10. Near-zero APEO

3. Application Scope

1. Suitable Substrates: Cement base, gypsum board, putty base, cement board, PVC board, etc.

2. Application Scenarios: Suitable for the decoration of wall and ceiling surfaces in high-end residences, star-rated hotels, high-end office buildings, design studios, high-end commercial spaces, bathrooms, basements, etc.

4. Product Parameters

|

Product Name

|

Tauvis Interior Paint

|

|

Main Components

|

Water, additives, mineral fillers

|

|

Packaging Specification

|

20kg/barrel

|

|

Product Type

|

Water-based sand-textured architectural coating

|

|

Product Use

|

Suitable for indoor decoration

|

|

Construction Method

|

Transparent penetrating primer → Carrara → Tauvis Interior Paint → Polishing → Dust removal

|

|

Polishing Time

|

Polishing should be carried out within 12 hours after the completion of construction. The longer the time, the higher the hardness, and the more difficult the polishing.

|

|

Product Model

|

☑ ZL-TWS-9600YGS Coarse

☑ ZL-TWS-9800YGS Medium

☑ ZL-TWS-9900YGS Fine

☑ ZL-TWS-9600YGS Extra Coarse

|

|

Color Matching

|

Color numbers can be selected according to the Tauvis color card, or water-soluble colorants with good weather resistance can be used for self-coloring. The use of color powder is prohibited.

|

|

Performance Description

|

The first 15 days after the completion of construction is the curing period. The hardness of the coating will gradually increase within about 30-45 days under natural drying conditions. If the surface of the coating is wiped with a wet towel, the hardness will be more prominent after drying!

|

|

Environmental Standard

|

GB 18582-2020

|

|

Performance Standard

|

JG/T 24-2018

|

|

Certification

|

Passed 3C certification and French A + certification

|

5. Testing Reference

Reference table for the limit of harmful substances in water-based interior wall coatings (GB 18582-2020): For details, please refer to the product test report.

|

Serial Number

|

Official Testing Standard Basis

|

Enterprise Implementation Standard

|

|

1

|

VOC Content

|

VOC Content

|

≤80g/L (Qualified)

|

Near-zero g/L

|

|

2

|

Formaldehyde Content

|

Formaldehyde Content

|

≤50mg/kg (Qualified)

|

Near-zero mg/kg

|

|

3

|

Total Content of Benzene Series [Limited to Benzene, Toluene, Xylene (Including Ethylbenzene)]

|

Total Content of Benzene Series [Limited to Benzene, Toluene, Xylene (Including Ethylbenzene)]

|

≤100mg/kg (Qualified)

|

Near-zero mg/kg

|

|

4

|

Total Lead (Pb) Content (Limited to Colored Paints and Putties)

|

Total Lead (Pb) Content (Limited to Colored Paints and Putties)

|

≤90mg/kg (Qualified)

|

Near-zero mg/kg

|

|

5

|

Soluble Heavy Metal Content (Limited to Colored Paints and Putties)

|

Cadmium (Cd) Content

|

≤75mg/kg (Qualified)

|

Near-zero mg/kg

|

|

Chromium (Cr) Content

|

≤60mg/kg (Qualified)

|

Near-zero mg/kg

|

|

Mercury (Hg) Content

|

≤60mg/kg (Qualified)

|

Near-zero mg/kg

|

|

6

|

Total Content of Alkylphenol Polyoxyethylene Ethers [Limited to Octylphenol Polyoxyethylene Ether (OPnEO) and Nonylphenol Polyoxyethylene Ether (NPnEO), n=2~16]

|

Total Content of Alkylphenol Polyoxyethylene Ethers [Limited to Octylphenol Polyoxyethylene Ether (OPnEO) and Nonylphenol Polyoxyethylene Ether (NPnEO), n=2-16]

|

≤1000mg/kg (Qualified)

|

Near-zero mg/kg

|

|

Near-zero mg/kg

|

|

Near-zero mg/kg

|

|

Near-zero mg/kg

|

|

EU Testing

|

|

Belgian VOC

|

Passed Belgian VOC testing

|

|

German AgBB

|

Passed German AgBB total carcinogen testing

|

|

French VOC Regulation

|

Meets Grade A + of French VOC Regulation

|

6.Technical Guidance

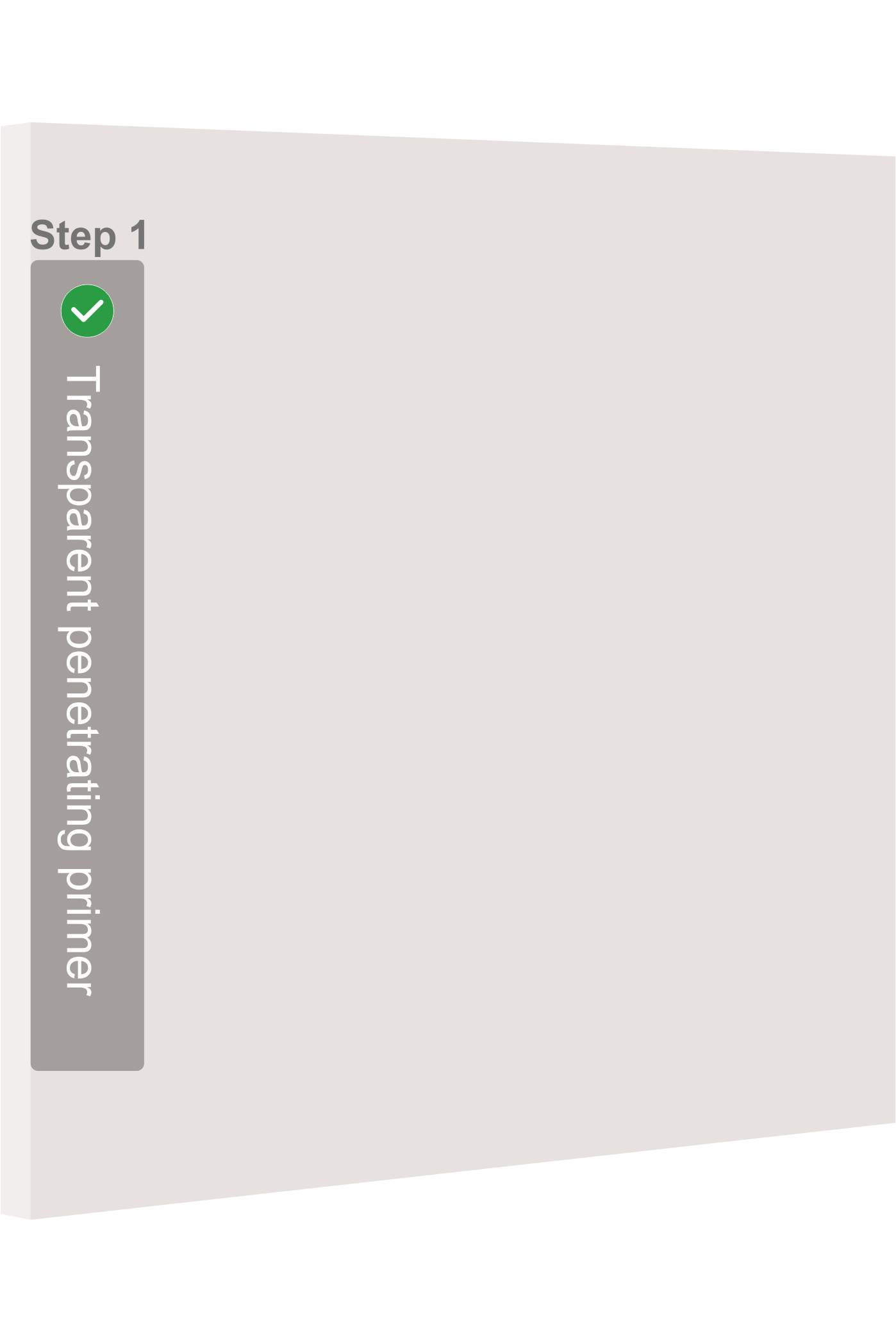

Construction Steps

|

Construction Step

|

Product Name

|

Construction Method

|

Construction Times

|

Usage Suggestion

|

Product Overview

|

|

Step 1

|

Transparent Penetrating Primer

|

Roller Coating-Horizontal and Vertical Crossing

|

1-2

|

☑Mandatory

|

Hardens and reinforces the putty base

|

|

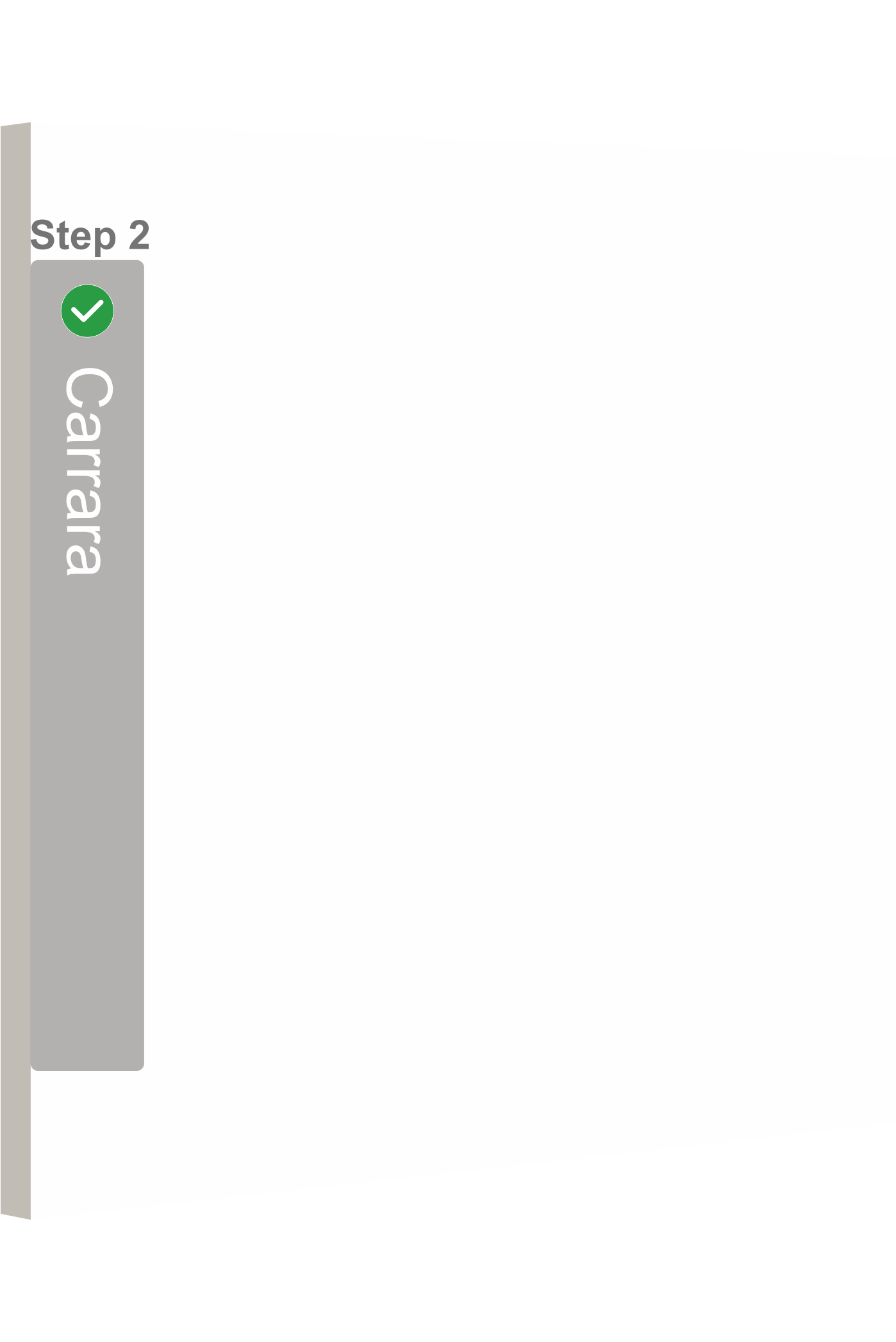

Step 2

|

Carrara

|

Roller Coating-Horizontal and Vertical Crossing

|

1

|

☑Mandatory

|

Improves the adhesion between the base and the main material and the color saturation

|

|

Step 3

|

Tauvis Interior Paint

|

Troweling

|

2

|

☑Mandatory

|

Creates texture

|

|

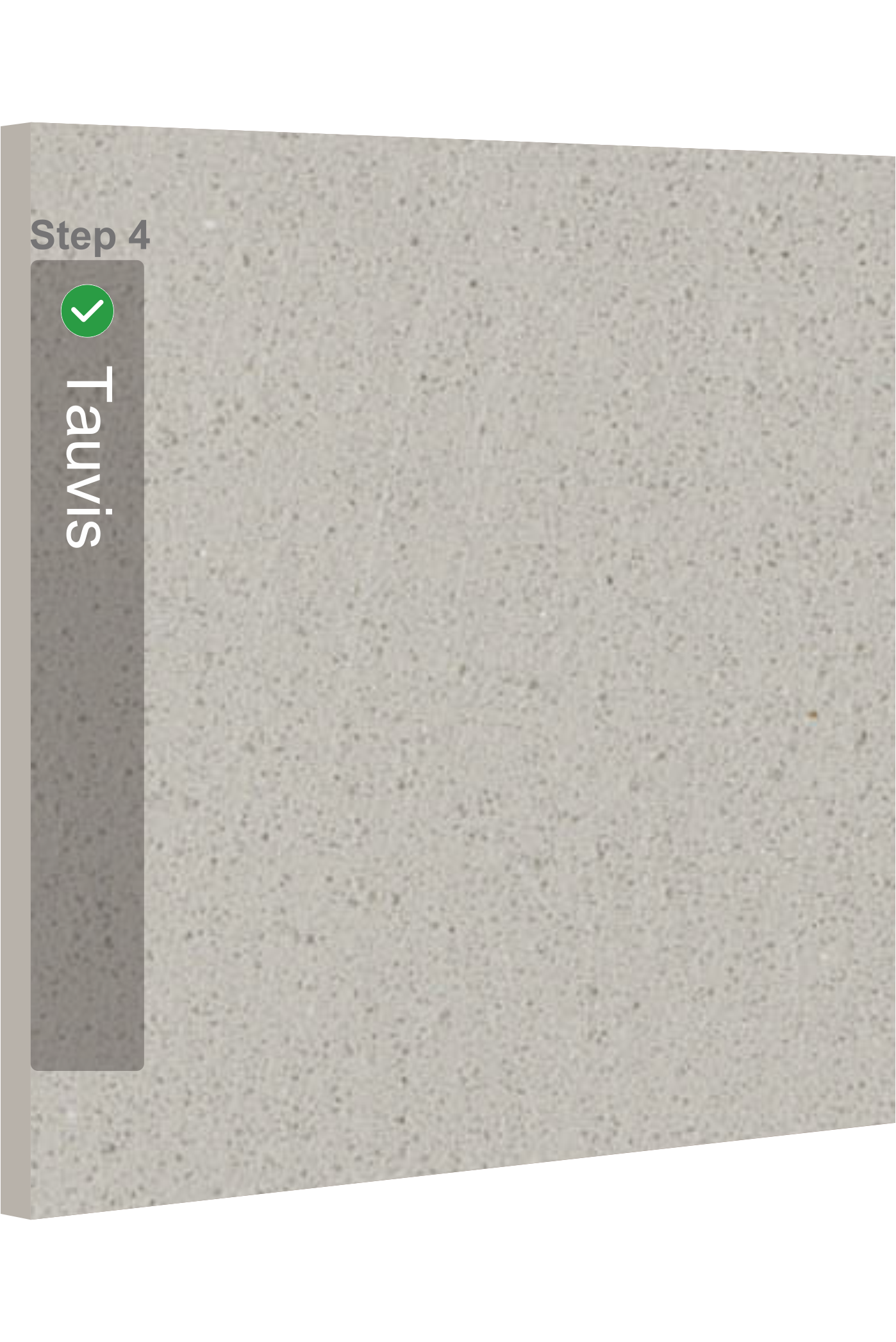

Step 4

|

/

|

Sanding

|

1-2

|

Sanding as needed

|

|

Step 5

|

Matte Transparent Protective Layer

|

Roller Coating / Wiping Coating

|

1

|

□Mandatory

☑Optional

|

Applying a topcoat may affect the hand feel and gloss of the finished product itself. Please be cautious!

|

Theoretical Spreading Rate

|

Product Name

|

Theoretical Spreading Rate (kg/1㎡)

|

Water Dilution Ratio (%)

|

Dry Film Thickness (mm)

|

|

Transparent Penetrating Primer

|

1kg/5㎡-7㎡

|

Prohibited

|

/

|

|

Carrara

|

1kg/3.5㎡-5㎡

|

5%-10%

|

/

|

|

Tauvis Extra Coarse

|

2.5kg-3kg/㎡

|

1%-3%

|

1.0mm-1.2mm

|

|

Tauvis Coarse

|

1.65kg-1.8kg/㎡

|

0.6mm-0.8mm

|

|

Tauvis Medium

|

1.0kg-1.2kg/㎡

|

0.3mm-0.5mm

|

|

Tauvis Fine

|

0.8kg-1.0kg/㎡

|

0.2mm-0.25mm

|

|

Matte Transparent Protective Layer

|

Determined by the roughness of the texture

|

5%-10%

|

/

|

Notes

1. The construction process is a fixed procedure. For the quality of the finished product, Steps 1 to 3 cannot be omitted. Step 1 can be constructed twice or once depending on the looseness of the putty base.

2. The spreading rate depends on the film thickness during construction, the construction texture, and the roughness of the base surface. The above data are theoretical average values obtained through practice and repeated laboratory tests.

3. To ensure the effect of the finished product, please strictly follow the water dilution ratio. If you have any questions, please consult the official technical personnel of the enterprise for guidance.

4. Due to the difference in dry film thickness, the dry film thickness in the above table is an average value.

5. The advantage of the topcoat layer is to improve the hardness and stain-resistant and scrub-resistant functions of the dry film of the coating. The disadvantage is that applying the topcoat will lose the hand feel of the artistic coating itself. Users can choose whether to use it according to the application scenario.

6. If you are not clear about the construction process, please follow the official WeChat public account of the enterprise or contact the professional technical personnel of the enterprise for guidance.

Base Treatment

1. Before construction, the base must be cleaned, kept flat, clean and dry, with no dust, oil, cement, etc. on the surface.

2. The moisture content of the base surface shall be ≤10%. The curing period of the new plaster base shall be ≥ 10 days in summer and ≥ 20 days in winter.

3. The pH value shall be < 9. Excessive alkalinity will cause discoloration and delamination of the coating.

Construction Conditions

1. The construction environment temperature range is 5℃-35℃. When the temperature is lower than 5℃, the water-based coating is easy to freeze and damage its structure; when the temperature is higher than 35℃, it is easy to cause cracking of the coating. The optimal construction temperature is 15℃-30℃.

2. The air humidity of the construction environment shall be < 80%. If the air humidity exceeds 80%, construction shall be suspended to avoid mildew or slow drying of the coating. Dehumidification equipment shall be used for indoor construction during the plum rain season.

Drying Time

1. The normal surface drying time of the coating is 4-6 hours.

2. However, the actual drying time is affected by the air circulation conditions, ambient temperature, and coating thickness at the construction site. Please determine it according to the on-site situation.

3. The given data is for guidance only. The actual drying time and the time for applying the next layer may be longer or shorter. You can consult the official technical personnel for communication and guidance.

7. Precautions

1. Before large-area construction, please make a sample for acceptance and sign for confirmation.

2. Construction personnel must receive professional training, and the construction site must be guided by the technical person in charge on site.

3. Before construction, the ground, furniture, doors, windows, etc. must be well protected to avoid unnecessary losses caused by slurry splashing. When cleaning tools, please pay attention to environmental hygiene. If slurry drips and adheres to the floor, toilet, bathtub, doors, and windows, it should be wiped clean immediately.

4. During the construction interval, the barrel lid should be tightly closed to prevent the surface of the slurry from forming a skin. The slurry that has been diluted with water cannot be poured back into the original package.

5. If the slurry accidentally gets into the eyes or mouth during construction, please immediately rinse the eyes with clean water and gargle. If there is any discomfort or accidental ingestion, please seek medical attention immediately.

8. Special Statement

All environmental protection coatings of FILOVIA are industrial-grade products. The environmental protection level of coatings is evaluated based on whether harmful substances are emitted during and after use. The environmental protection of coatings is not food-grade. Any form of demonstration of swallowing coatings to mislead users into purchasing is prohibited. Otherwise, the consequences shall be borne by the responsible party. If serious impacts are caused, our company will pursue legal responsibilities. Please guide users to purchase and use the products in a legal and compliant manner.

9. Storage Conditions

1. This product shall be sealed and stored in a dry and cool place at a temperature between 5℃ and 30℃. Avoid rain, direct sunlight, and low-temperature frost.

2. The shelf life is 24 months when the lid is not opened.

The finished effect of the artistic coating has a wide range of extensibility. If you have any questions about the specific construction and effect application, please contact us.

AgBB VOC TEST

Nationaler Normprüfbericht

FILOVIA (Asia-Pacific Operation Headquarters-Shanghai, China)

Tel: +86-400-961-6660

Chinese Official Website: https://www.filoviatl.com

International Official Website: https://www.filoviapa.com

Corporate Email: filoviatl@163.com

YAWEIDE (SHANGHAI) COATINGS CO., LTD

FILOVIA Germany

Only produces high-end and high-quality coatings